BACKGROUND INFO, LEGAL ASPECTS, CAREFULNESS ETC

(things which are supposed to be understood and not

repeated with each new elsketch project page)

http://www.stamash.com/secs_stamash_educational_centers/elsketch/

OVERVIEW OVER ONLINE AVAILABLE ELSKETCH PROJECTS --

http://www.stamash.com/secs_stamash_educational_centers/elsketch/sitemap/

-- THESE HAVE ALL BEEN CAREFULLY STUDIED IN REAL LIFE,

NOT JUST AS AN EMULATION ON A COMPUTER, AND FOUND TO

WORK AS PROMISED; NOTE THAT SUCH AS AM MW RADIOS IS

-- FOR ANY LONG-RANGE USE -- EXTREMELY TIED UP TO

ALL SORTS OF WEATHER CONDITIONS AND THE EXTENT TO

WHICH IT IS NIGHTTIME

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

For the G15 Multiversity: Background works

Also part of the Stamash Educational CenterS, SECS

For general info about G15 Yoga6dorg see also www.norskesites.org/fic3

In general terms, we might use the following

vocabulary: Each Elsketch project constitutes

also a report over successfully completed

electronics development and implementation work,

in a sense a bit of 'neopopperian research',

intended to be replicated in an improvised,

intuitive, playful way by anybody who likes

to educate herself in this way.

This report is dated August 15, 2013. For

general info about copyright confer the spirit

of honoring acknowledgements as found in our

www.yoga4d.org/cfdl.txt.

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

Elsketch: Winding your own variable capacitors for the 1st radio module

-- unbearably easy, given some metal paper, plastic and glue,

and stuff

[note: for ease of composing the materials, frequent mentions

in the Elsketch texts are made of things which belong to the

future -- future Elsketch activities include making even a

whole G15 computer, and parallel activities are also referred

to in the same manner, such as the chemical educational activity

we have named Atomlite. apart from these references to things not

yet done as if they have been done, each elsketch project describes

a project actually carried out to success, and well tested, and

fully doable in the present by following the instructions.]

You've got the radio, you want to loosen the prefabricated

variable capacitor and make your own. You already have read

the starting-point for this radio. You have perhaps already

played around with your own ferrite coils. I'll take the

liberty of going straight to the technicalities here, since

those other two descriptions around the 1st radio module

allowed for plenty of philosophising.

THE WAY

Cut metal paper -- thin leaf aluminium for instance, or another

type of metal that fairly easily conduct electricity -- about

the size of half a normal sheet of paper, or less, say 18 times

13 centimeter. Cut off a luxuriously large corner.

Get the type of copper wire which is composed of myriad

tiny copper threads. Rip off the isolation. Spread the

copper threads out. Get a little tin on some of them, both

sides of the copper threads, with the tinner -- just a tiny

little bit, no heavy drops (just smooth the tin along the

copper, so as to dress some of the copper threads up with tin,

it's a kind of lingerie for the long legs of the copper girl).

Put them on the metal paper -- so that you have the cleanest,

most metallic part of the metal paper facing one another except

for the isolation you're putting on it, with the wires on the

other sides. In other words, you have two very clean clear

straight metal papers near one another but they are isolated

(at least one of them must be well isolated, but since they

are thin it can be good for the strength of the whole thingy

that both of them are isolated by strong glue or plastic).

And we want to connect wires to these metal papers and we

do so by spreading out very very thin copper threads of the

type that's already typically used e.g. in higher voltage

wires. We spread them out thin so that we won't create

bumps in the papers. We have one wire that's absolutely

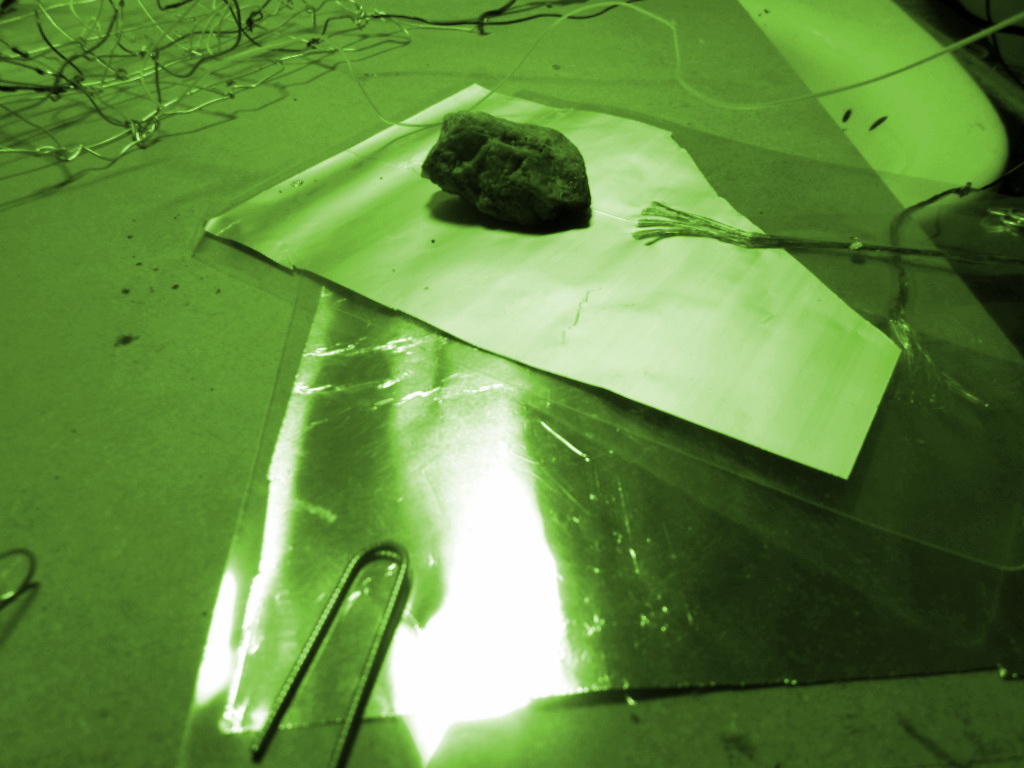

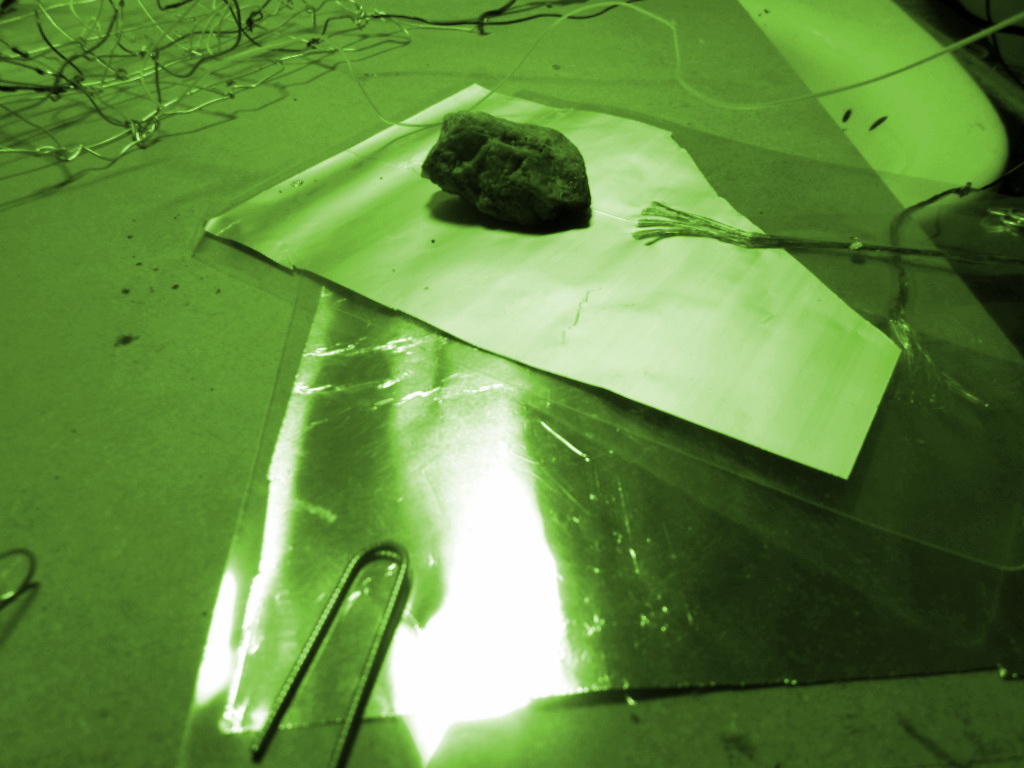

on top (see image), and another wire that's absolutely

underneath the bottom metal plate -- leaving the cleanest

clearest parallel feel of the metal plates intact, we don't

want to clutter anything.

We want to be able to move those isolated metal

plates on top of one another and then off one another, in a

gradual movement. We want the copper threads to stick firmly

to the metal, and not slide. But the metal film is usually too

thin that you can tin the copper to it, heat will burn it up.

That's why we spread it out and glue it on or push them on with

plastic around and then glue or melt the plastic to push them.

Put either loads of epoxy on one side so as to cover absolutely

all of the metal without fail, yet somewhat smoothly, or glue

plastic to it; or if you have a machine that can melt two sheets

of thin plastic to a sheet of paper then very carefully let that

machine melt the plastic around the metal paper -- with enormous

attention to the copper threads, so they don't get stuck in the

machine (there might be settings on some machines for more

flexibility as to what it is fed with). Or, if you don't have

glue, just put plastic around the metal paper, and try and tie

the copper threads very gently in some tiny holes you try and

make in the metal paper.

Not a necessity but you can then make a hole in the proper

corner and use a tool to bend some steel wire of a millimeter

so as to keep them together in just that corner -- twirl the

steel wire around and cut it so it doesn't touch any wires,

and be sure it doesn't get anywhere near the metal here --

see photo.

Also not a necessity in all cases but it can help to put a

heavy non-metallic object like a stone on top of the whole to

push them towards one another.

Yeah, and put some kind of clip to keep the bottommost paper

in place on the table or wherever you have your elsketch work.

We want to slide the topmost paper with the bottommost paper

being stable.

THE RESULT

It is great fun to engage in precise-tuning of the radio --

trying out different coils -- with the self-made capacitor,

if you already have got the enthusiasm going for this kind

of first-hand electronics radio and you started out using a

prefabricated variable capacitor. You'll notice that for most

coils, in most circumstances, given most types of design, the

bulk of the stations come in when the papers are slided very

much off one another -- more than in the pictures for some

coils.

But of great importance is the distance that the papers

have. When you adjust, you could adjust by having a tiny

corner of the topmost sheaf bent up -- the adjustment makes

sense if you can move the topmost sheaf without giving

pressure on it -- at least if you have sheaves that have a

little bounce in them, so that there's naturally some

air between the sheaves -- at least on the portion not

having a stone on top. The more distance the metal papers

have, the less is the capacitance, and the more the papers

must be on top of one another to give capacitance. You can

experiment with putting something like paper in between

just for fun, to sense the difference (although consider

that only an experiment, as paper shouldn't be made a

fixed part of electronics equipment because of the natural

consideration to have elements that aren't very fireprone

at all). If there's too much paper, it will decrease the

range of the capacitor too much. If the sheaves are touching

one another too much, the capacitance is so great that

it may go out of range that way. With a little bounce in

the sheaves, and the stone on the side, you can get a lot

of stability in the arrangement.

If you're doing this step by step, making the radio module

with prefabricated coils and variable capacitor, and also

with an audio module, and have just made your own coil and

your own variable capacitor, then there are two alternative

obvious next steps: make your own audio module out of

transistors, or make a own transmitter to get your own

stuff across to your radio.

Increased stability of the result: find some way to keep

the wires that goes to the rest of the radio module, tinned

to the copper threads, outside of the plates themselves. If

the wires touch the plates sometimes, dangling over like you

can see on the images on top, this dangling will tune and

retune various stations -- in addition to the sweet shift of

frequencies that always happens with MW as the belt of

blackness moves with the Sun on the other side of the planet.

As this belt of blackness moves, some stations that came

easily in before the darknest part of the night fade and

new ones come become available -- in addition to the changes

that weather conditions provide.

There is ABSOLUTELY NO REDUCTION IN QUALITY of reception when

we make our own variable capacitor this way. There is no

reduction at all -- neither of intensity nor of reception

clarity or anything else. Radio capacitors are, simply,

delightfully easy to make!

Let's note in general that since 1nf is one thousand pf, and

it takes easily five hundred nf -- five hundred thousand pf,

that is, to have an easy time working with audio amplifiers,

and they would enormously like such as 50 mf -- 50.000nf --

which is to say, 50 million picofarad -- for still better

sound effects -- we are into the need to vary materials out

of which we construct capacitors of when we go much higher

up in farads than what we did in this project. For a good

AM MW radio variable capacitor, up to some 200 pf is just

perfect, just fine, and that's probably much what you just

made, if you followed the instructions here. If you double

the size of that you are still not anywhere near 1nf. To get

all the way up to 1 mf this way we would have to fill a house

with the capacitor. Instead, the notion is that we can put

some chemical in between the two plates, or even make one of

the plates into something special, so that we get a light

chemical reaction that can preserve a little electricity for

a little while, then release it; then allow a recharging.

In this perspective, a rechargable large stable robust car

battery is like an enormously huge capacitor of many farad,

and it may be made of lead in sulphuric acid (sulphur dioxide

in water). More about such stuff in Atomlite, where we

construct all the more chemical Elsketch components.

Let's go on!

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

BACKGROUND INFO, LEGAL ASPECTS, CAREFULNESS ETC

(things which are supposed to be understood and not

repeated with each new elsketch project page)

http://www.stamash.com/secs_stamash_educational_centers/elsketch/

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

[note: for ease of composing the materials, frequent mentions

in the Elsketch texts are made of things which belong to the

future -- future Elsketch activities include making even a

whole G15 computer, and parallel activities are also referred

to in the same manner, such as the chemical educational activity

we have named Atomlite. apart from these references to things not

yet done as if they have been done, each elsketch project describes

a project actually carried out to success, and well tested, and

fully doable in the present by following the instructions.]

You've got the radio, you want to loosen the prefabricated

variable capacitor and make your own. You already have read

the starting-point for this radio. You have perhaps already

played around with your own ferrite coils. I'll take the

liberty of going straight to the technicalities here, since

those other two descriptions around the 1st radio module

allowed for plenty of philosophising.

THE WAY

Cut metal paper -- thin leaf aluminium for instance, or another

type of metal that fairly easily conduct electricity -- about

the size of half a normal sheet of paper, or less, say 18 times

13 centimeter. Cut off a luxuriously large corner.

Get the type of copper wire which is composed of myriad

tiny copper threads. Rip off the isolation. Spread the

copper threads out. Get a little tin on some of them, both

sides of the copper threads, with the tinner -- just a tiny

little bit, no heavy drops (just smooth the tin along the

copper, so as to dress some of the copper threads up with tin,

it's a kind of lingerie for the long legs of the copper girl).

Put them on the metal paper -- so that you have the cleanest,

most metallic part of the metal paper facing one another except

for the isolation you're putting on it, with the wires on the

other sides. In other words, you have two very clean clear

straight metal papers near one another but they are isolated

(at least one of them must be well isolated, but since they

are thin it can be good for the strength of the whole thingy

that both of them are isolated by strong glue or plastic).

And we want to connect wires to these metal papers and we

do so by spreading out very very thin copper threads of the

type that's already typically used e.g. in higher voltage

wires. We spread them out thin so that we won't create

bumps in the papers. We have one wire that's absolutely

on top (see image), and another wire that's absolutely

underneath the bottom metal plate -- leaving the cleanest

clearest parallel feel of the metal plates intact, we don't

want to clutter anything.

We want to be able to move those isolated metal

plates on top of one another and then off one another, in a

gradual movement. We want the copper threads to stick firmly

to the metal, and not slide. But the metal film is usually too

thin that you can tin the copper to it, heat will burn it up.

That's why we spread it out and glue it on or push them on with

plastic around and then glue or melt the plastic to push them.

Put either loads of epoxy on one side so as to cover absolutely

all of the metal without fail, yet somewhat smoothly, or glue

plastic to it; or if you have a machine that can melt two sheets

of thin plastic to a sheet of paper then very carefully let that

machine melt the plastic around the metal paper -- with enormous

attention to the copper threads, so they don't get stuck in the

machine (there might be settings on some machines for more

flexibility as to what it is fed with). Or, if you don't have

glue, just put plastic around the metal paper, and try and tie

the copper threads very gently in some tiny holes you try and

make in the metal paper.

Not a necessity but you can then make a hole in the proper

corner and use a tool to bend some steel wire of a millimeter

so as to keep them together in just that corner -- twirl the

steel wire around and cut it so it doesn't touch any wires,

and be sure it doesn't get anywhere near the metal here --

see photo.

Also not a necessity in all cases but it can help to put a

heavy non-metallic object like a stone on top of the whole to

push them towards one another.

Yeah, and put some kind of clip to keep the bottommost paper

in place on the table or wherever you have your elsketch work.

We want to slide the topmost paper with the bottommost paper

being stable.

THE RESULT

It is great fun to engage in precise-tuning of the radio --

trying out different coils -- with the self-made capacitor,

if you already have got the enthusiasm going for this kind

of first-hand electronics radio and you started out using a

prefabricated variable capacitor. You'll notice that for most

coils, in most circumstances, given most types of design, the

bulk of the stations come in when the papers are slided very

much off one another -- more than in the pictures for some

coils.

But of great importance is the distance that the papers

have. When you adjust, you could adjust by having a tiny

corner of the topmost sheaf bent up -- the adjustment makes

sense if you can move the topmost sheaf without giving

pressure on it -- at least if you have sheaves that have a

little bounce in them, so that there's naturally some

air between the sheaves -- at least on the portion not

having a stone on top. The more distance the metal papers

have, the less is the capacitance, and the more the papers

must be on top of one another to give capacitance. You can

experiment with putting something like paper in between

just for fun, to sense the difference (although consider

that only an experiment, as paper shouldn't be made a

fixed part of electronics equipment because of the natural

consideration to have elements that aren't very fireprone

at all). If there's too much paper, it will decrease the

range of the capacitor too much. If the sheaves are touching

one another too much, the capacitance is so great that

it may go out of range that way. With a little bounce in

the sheaves, and the stone on the side, you can get a lot

of stability in the arrangement.

If you're doing this step by step, making the radio module

with prefabricated coils and variable capacitor, and also

with an audio module, and have just made your own coil and

your own variable capacitor, then there are two alternative

obvious next steps: make your own audio module out of

transistors, or make a own transmitter to get your own

stuff across to your radio.

Increased stability of the result: find some way to keep

the wires that goes to the rest of the radio module, tinned

to the copper threads, outside of the plates themselves. If

the wires touch the plates sometimes, dangling over like you

can see on the images on top, this dangling will tune and

retune various stations -- in addition to the sweet shift of

frequencies that always happens with MW as the belt of

blackness moves with the Sun on the other side of the planet.

As this belt of blackness moves, some stations that came

easily in before the darknest part of the night fade and

new ones come become available -- in addition to the changes

that weather conditions provide.

There is ABSOLUTELY NO REDUCTION IN QUALITY of reception when

we make our own variable capacitor this way. There is no

reduction at all -- neither of intensity nor of reception

clarity or anything else. Radio capacitors are, simply,

delightfully easy to make!

Let's note in general that since 1nf is one thousand pf, and

it takes easily five hundred nf -- five hundred thousand pf,

that is, to have an easy time working with audio amplifiers,

and they would enormously like such as 50 mf -- 50.000nf --

which is to say, 50 million picofarad -- for still better

sound effects -- we are into the need to vary materials out

of which we construct capacitors of when we go much higher

up in farads than what we did in this project. For a good

AM MW radio variable capacitor, up to some 200 pf is just

perfect, just fine, and that's probably much what you just

made, if you followed the instructions here. If you double

the size of that you are still not anywhere near 1nf. To get

all the way up to 1 mf this way we would have to fill a house

with the capacitor. Instead, the notion is that we can put

some chemical in between the two plates, or even make one of

the plates into something special, so that we get a light

chemical reaction that can preserve a little electricity for

a little while, then release it; then allow a recharging.

In this perspective, a rechargable large stable robust car

battery is like an enormously huge capacitor of many farad,

and it may be made of lead in sulphuric acid (sulphur dioxide

in water). More about such stuff in Atomlite, where we

construct all the more chemical Elsketch components.

Let's go on!

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

BACKGROUND INFO, LEGAL ASPECTS, CAREFULNESS ETC

(things which are supposed to be understood and not

repeated with each new elsketch project page)

http://www.stamash.com/secs_stamash_educational_centers/elsketch/

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

[note: for ease of composing the materials, frequent mentions

in the Elsketch texts are made of things which belong to the

future -- future Elsketch activities include making even a

whole G15 computer, and parallel activities are also referred

to in the same manner, such as the chemical educational activity

we have named Atomlite. apart from these references to things not

yet done as if they have been done, each elsketch project describes

a project actually carried out to success, and well tested, and

fully doable in the present by following the instructions.]

You've got the radio, you want to loosen the prefabricated

variable capacitor and make your own. You already have read

the starting-point for this radio. You have perhaps already

played around with your own ferrite coils. I'll take the

liberty of going straight to the technicalities here, since

those other two descriptions around the 1st radio module

allowed for plenty of philosophising.

THE WAY

Cut metal paper -- thin leaf aluminium for instance, or another

type of metal that fairly easily conduct electricity -- about

the size of half a normal sheet of paper, or less, say 18 times

13 centimeter. Cut off a luxuriously large corner.

Get the type of copper wire which is composed of myriad

tiny copper threads. Rip off the isolation. Spread the

copper threads out. Get a little tin on some of them, both

sides of the copper threads, with the tinner -- just a tiny

little bit, no heavy drops (just smooth the tin along the

copper, so as to dress some of the copper threads up with tin,

it's a kind of lingerie for the long legs of the copper girl).

Put them on the metal paper -- so that you have the cleanest,

most metallic part of the metal paper facing one another except

for the isolation you're putting on it, with the wires on the

other sides. In other words, you have two very clean clear

straight metal papers near one another but they are isolated

(at least one of them must be well isolated, but since they

are thin it can be good for the strength of the whole thingy

that both of them are isolated by strong glue or plastic).

And we want to connect wires to these metal papers and we

do so by spreading out very very thin copper threads of the

type that's already typically used e.g. in higher voltage

wires. We spread them out thin so that we won't create

bumps in the papers. We have one wire that's absolutely

on top (see image), and another wire that's absolutely

underneath the bottom metal plate -- leaving the cleanest

clearest parallel feel of the metal plates intact, we don't

want to clutter anything.

We want to be able to move those isolated metal

plates on top of one another and then off one another, in a

gradual movement. We want the copper threads to stick firmly

to the metal, and not slide. But the metal film is usually too

thin that you can tin the copper to it, heat will burn it up.

That's why we spread it out and glue it on or push them on with

plastic around and then glue or melt the plastic to push them.

Put either loads of epoxy on one side so as to cover absolutely

all of the metal without fail, yet somewhat smoothly, or glue

plastic to it; or if you have a machine that can melt two sheets

of thin plastic to a sheet of paper then very carefully let that

machine melt the plastic around the metal paper -- with enormous

attention to the copper threads, so they don't get stuck in the

machine (there might be settings on some machines for more

flexibility as to what it is fed with). Or, if you don't have

glue, just put plastic around the metal paper, and try and tie

the copper threads very gently in some tiny holes you try and

make in the metal paper.

Not a necessity but you can then make a hole in the proper

corner and use a tool to bend some steel wire of a millimeter

so as to keep them together in just that corner -- twirl the

steel wire around and cut it so it doesn't touch any wires,

and be sure it doesn't get anywhere near the metal here --

see photo.

Also not a necessity in all cases but it can help to put a

heavy non-metallic object like a stone on top of the whole to

push them towards one another.

Yeah, and put some kind of clip to keep the bottommost paper

in place on the table or wherever you have your elsketch work.

We want to slide the topmost paper with the bottommost paper

being stable.

THE RESULT

It is great fun to engage in precise-tuning of the radio --

trying out different coils -- with the self-made capacitor,

if you already have got the enthusiasm going for this kind

of first-hand electronics radio and you started out using a

prefabricated variable capacitor. You'll notice that for most

coils, in most circumstances, given most types of design, the

bulk of the stations come in when the papers are slided very

much off one another -- more than in the pictures for some

coils.

But of great importance is the distance that the papers

have. When you adjust, you could adjust by having a tiny

corner of the topmost sheaf bent up -- the adjustment makes

sense if you can move the topmost sheaf without giving

pressure on it -- at least if you have sheaves that have a

little bounce in them, so that there's naturally some

air between the sheaves -- at least on the portion not

having a stone on top. The more distance the metal papers

have, the less is the capacitance, and the more the papers

must be on top of one another to give capacitance. You can

experiment with putting something like paper in between

just for fun, to sense the difference (although consider

that only an experiment, as paper shouldn't be made a

fixed part of electronics equipment because of the natural

consideration to have elements that aren't very fireprone

at all). If there's too much paper, it will decrease the

range of the capacitor too much. If the sheaves are touching

one another too much, the capacitance is so great that

it may go out of range that way. With a little bounce in

the sheaves, and the stone on the side, you can get a lot

of stability in the arrangement.

If you're doing this step by step, making the radio module

with prefabricated coils and variable capacitor, and also

with an audio module, and have just made your own coil and

your own variable capacitor, then there are two alternative

obvious next steps: make your own audio module out of

transistors, or make a own transmitter to get your own

stuff across to your radio.

Increased stability of the result: find some way to keep

the wires that goes to the rest of the radio module, tinned

to the copper threads, outside of the plates themselves. If

the wires touch the plates sometimes, dangling over like you

can see on the images on top, this dangling will tune and

retune various stations -- in addition to the sweet shift of

frequencies that always happens with MW as the belt of

blackness moves with the Sun on the other side of the planet.

As this belt of blackness moves, some stations that came

easily in before the darknest part of the night fade and

new ones come become available -- in addition to the changes

that weather conditions provide.

There is ABSOLUTELY NO REDUCTION IN QUALITY of reception when

we make our own variable capacitor this way. There is no

reduction at all -- neither of intensity nor of reception

clarity or anything else. Radio capacitors are, simply,

delightfully easy to make!

Let's note in general that since 1nf is one thousand pf, and

it takes easily five hundred nf -- five hundred thousand pf,

that is, to have an easy time working with audio amplifiers,

and they would enormously like such as 50 mf -- 50.000nf --

which is to say, 50 million picofarad -- for still better

sound effects -- we are into the need to vary materials out

of which we construct capacitors of when we go much higher

up in farads than what we did in this project. For a good

AM MW radio variable capacitor, up to some 200 pf is just

perfect, just fine, and that's probably much what you just

made, if you followed the instructions here. If you double

the size of that you are still not anywhere near 1nf. To get

all the way up to 1 mf this way we would have to fill a house

with the capacitor. Instead, the notion is that we can put

some chemical in between the two plates, or even make one of

the plates into something special, so that we get a light

chemical reaction that can preserve a little electricity for

a little while, then release it; then allow a recharging.

In this perspective, a rechargable large stable robust car

battery is like an enormously huge capacitor of many farad,

and it may be made of lead in sulphuric acid (sulphur dioxide

in water). More about such stuff in Atomlite, where we

construct all the more chemical Elsketch components.

Let's go on!

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

BACKGROUND INFO, LEGAL ASPECTS, CAREFULNESS ETC

(things which are supposed to be understood and not

repeated with each new elsketch project page)

http://www.stamash.com/secs_stamash_educational_centers/elsketch/

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

[note: for ease of composing the materials, frequent mentions

in the Elsketch texts are made of things which belong to the

future -- future Elsketch activities include making even a

whole G15 computer, and parallel activities are also referred

to in the same manner, such as the chemical educational activity

we have named Atomlite. apart from these references to things not

yet done as if they have been done, each elsketch project describes

a project actually carried out to success, and well tested, and

fully doable in the present by following the instructions.]

You've got the radio, you want to loosen the prefabricated

variable capacitor and make your own. You already have read

the starting-point for this radio. You have perhaps already

played around with your own ferrite coils. I'll take the

liberty of going straight to the technicalities here, since

those other two descriptions around the 1st radio module

allowed for plenty of philosophising.

THE WAY

Cut metal paper -- thin leaf aluminium for instance, or another

type of metal that fairly easily conduct electricity -- about

the size of half a normal sheet of paper, or less, say 18 times

13 centimeter. Cut off a luxuriously large corner.

Get the type of copper wire which is composed of myriad

tiny copper threads. Rip off the isolation. Spread the

copper threads out. Get a little tin on some of them, both

sides of the copper threads, with the tinner -- just a tiny

little bit, no heavy drops (just smooth the tin along the

copper, so as to dress some of the copper threads up with tin,

it's a kind of lingerie for the long legs of the copper girl).

Put them on the metal paper -- so that you have the cleanest,

most metallic part of the metal paper facing one another except

for the isolation you're putting on it, with the wires on the

other sides. In other words, you have two very clean clear

straight metal papers near one another but they are isolated

(at least one of them must be well isolated, but since they

are thin it can be good for the strength of the whole thingy

that both of them are isolated by strong glue or plastic).

And we want to connect wires to these metal papers and we

do so by spreading out very very thin copper threads of the

type that's already typically used e.g. in higher voltage

wires. We spread them out thin so that we won't create

bumps in the papers. We have one wire that's absolutely

on top (see image), and another wire that's absolutely

underneath the bottom metal plate -- leaving the cleanest

clearest parallel feel of the metal plates intact, we don't

want to clutter anything.

We want to be able to move those isolated metal

plates on top of one another and then off one another, in a

gradual movement. We want the copper threads to stick firmly

to the metal, and not slide. But the metal film is usually too

thin that you can tin the copper to it, heat will burn it up.

That's why we spread it out and glue it on or push them on with

plastic around and then glue or melt the plastic to push them.

Put either loads of epoxy on one side so as to cover absolutely

all of the metal without fail, yet somewhat smoothly, or glue

plastic to it; or if you have a machine that can melt two sheets

of thin plastic to a sheet of paper then very carefully let that

machine melt the plastic around the metal paper -- with enormous

attention to the copper threads, so they don't get stuck in the

machine (there might be settings on some machines for more

flexibility as to what it is fed with). Or, if you don't have

glue, just put plastic around the metal paper, and try and tie

the copper threads very gently in some tiny holes you try and

make in the metal paper.

Not a necessity but you can then make a hole in the proper

corner and use a tool to bend some steel wire of a millimeter

so as to keep them together in just that corner -- twirl the

steel wire around and cut it so it doesn't touch any wires,

and be sure it doesn't get anywhere near the metal here --

see photo.

Also not a necessity in all cases but it can help to put a

heavy non-metallic object like a stone on top of the whole to

push them towards one another.

Yeah, and put some kind of clip to keep the bottommost paper

in place on the table or wherever you have your elsketch work.

We want to slide the topmost paper with the bottommost paper

being stable.

THE RESULT

It is great fun to engage in precise-tuning of the radio --

trying out different coils -- with the self-made capacitor,

if you already have got the enthusiasm going for this kind

of first-hand electronics radio and you started out using a

prefabricated variable capacitor. You'll notice that for most

coils, in most circumstances, given most types of design, the

bulk of the stations come in when the papers are slided very

much off one another -- more than in the pictures for some

coils.

But of great importance is the distance that the papers

have. When you adjust, you could adjust by having a tiny

corner of the topmost sheaf bent up -- the adjustment makes

sense if you can move the topmost sheaf without giving

pressure on it -- at least if you have sheaves that have a

little bounce in them, so that there's naturally some

air between the sheaves -- at least on the portion not

having a stone on top. The more distance the metal papers

have, the less is the capacitance, and the more the papers

must be on top of one another to give capacitance. You can

experiment with putting something like paper in between

just for fun, to sense the difference (although consider

that only an experiment, as paper shouldn't be made a

fixed part of electronics equipment because of the natural

consideration to have elements that aren't very fireprone

at all). If there's too much paper, it will decrease the

range of the capacitor too much. If the sheaves are touching

one another too much, the capacitance is so great that

it may go out of range that way. With a little bounce in

the sheaves, and the stone on the side, you can get a lot

of stability in the arrangement.

If you're doing this step by step, making the radio module

with prefabricated coils and variable capacitor, and also

with an audio module, and have just made your own coil and

your own variable capacitor, then there are two alternative

obvious next steps: make your own audio module out of

transistors, or make a own transmitter to get your own

stuff across to your radio.

Increased stability of the result: find some way to keep

the wires that goes to the rest of the radio module, tinned

to the copper threads, outside of the plates themselves. If

the wires touch the plates sometimes, dangling over like you

can see on the images on top, this dangling will tune and

retune various stations -- in addition to the sweet shift of

frequencies that always happens with MW as the belt of

blackness moves with the Sun on the other side of the planet.

As this belt of blackness moves, some stations that came

easily in before the darknest part of the night fade and

new ones come become available -- in addition to the changes

that weather conditions provide.

There is ABSOLUTELY NO REDUCTION IN QUALITY of reception when

we make our own variable capacitor this way. There is no

reduction at all -- neither of intensity nor of reception

clarity or anything else. Radio capacitors are, simply,

delightfully easy to make!

Let's note in general that since 1nf is one thousand pf, and

it takes easily five hundred nf -- five hundred thousand pf,

that is, to have an easy time working with audio amplifiers,

and they would enormously like such as 50 mf -- 50.000nf --

which is to say, 50 million picofarad -- for still better

sound effects -- we are into the need to vary materials out

of which we construct capacitors of when we go much higher

up in farads than what we did in this project. For a good

AM MW radio variable capacitor, up to some 200 pf is just

perfect, just fine, and that's probably much what you just

made, if you followed the instructions here. If you double

the size of that you are still not anywhere near 1nf. To get

all the way up to 1 mf this way we would have to fill a house

with the capacitor. Instead, the notion is that we can put

some chemical in between the two plates, or even make one of

the plates into something special, so that we get a light

chemical reaction that can preserve a little electricity for

a little while, then release it; then allow a recharging.

In this perspective, a rechargable large stable robust car

battery is like an enormously huge capacitor of many farad,

and it may be made of lead in sulphuric acid (sulphur dioxide

in water). More about such stuff in Atomlite, where we

construct all the more chemical Elsketch components.

Let's go on!

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

BACKGROUND INFO, LEGAL ASPECTS, CAREFULNESS ETC

(things which are supposed to be understood and not

repeated with each new elsketch project page)

http://www.stamash.com/secs_stamash_educational_centers/elsketch/

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________